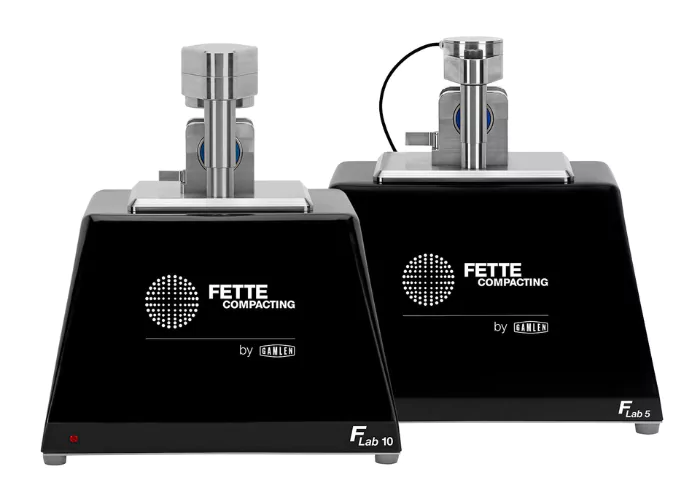

Quality by Design principles (QbD) state that high quality products are only achieved through understanding both, your material and process. In this context, it is crucial to precisely understand the compaction properties of all materials even before production. The F Lab 5 and F Lab 10 have been specially developed for this purpose. They allow you to fully characterize the compaction behavior of your powder.

The data supplied will benefit you throughout the entire product life cycle: from development and optimization through quality control in the ongoing manufacturing process.

Fette Flab/R&D

Introduction

Quality by Design principles (QbD) state that high quality products are only achieved through understanding both, your material and process. In this context, it is crucial to precisely understand the compaction properties of all materials even before production. The F Lab 5 and F Lab 10 have been specially developed for this purpose. They allow you to fully characterize the compaction behavior of your powder.

The data supplied will benefit you throughout the entire product life cycle: from development and optimization through quality control in the ongoing manufacturing process.

Data from all instruments is automatically collected by the dashboard analysis software on the respective laptop or PC. This gives you a full overview of powder properties in just 30 minutes.

Alternatively, you can use the F Lab 5 or F Lab 10 in combination with your existing measuring instruments.

The advantages for you

- You develop products faster and easier.

- Reduce time-to-market.

- During development and in production, you make decisions based on sound data.

- Faults can be analyzed more quickly – downtimes are reduced.

- No experience with compaction analysis is required.

- Small footprint, easy handling and cleaning.

Technical Info

| Flab 5 | Flab 10 | |

|---|---|---|

| Maximum load (kg) | 500 | 1,000 |

| Punch size range (diameter) | 1 - 10 | 3 - 15 |

| Compaction rate (mm/s) | 0.01 - 3 | 0.01 - 3 |

| Data capture rate (Hz) | 200 | 200 |

| Load cell travel (mm) | 30 | 40 |

| Load cell resolution | 1:5000 | 1:5000 |

| Clibration | Dead weights or proving ring | |

| Power requirements | 90 - 240 VAC 3.15A | |

| Dimensions | 310 x 270 x 375 | 320 x 285 x 388 |

| Weight | 16 | 24 |