Automatic visual inspection machine for ampoules, vials, cartridges and syringes.

The AV-E is the cutting-edge technology for the high-speed automatic inspection of pharmaceutical products such as vials, cartridges, ampoules¿ and syringes (mod. AV-EGS), ¿which represents the ideal solution to ensure that SVP products are essentially free of particulate and cosmetic defects.

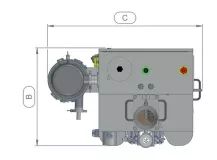

iSpray

Introduction

The iSpray is a unique punch face and die wall lubrication system that continuously sprays dry lubricant onto tablet press, delivering a consistent and verifiable amount of lubricant onto the tablet outer surface.

It is the ideal solution to cope with issues such as capping, sticking, too high ejection force, chemical incompatibility with formulation or poor dissolution.

The system applies only the needed amount of lubricant while vacuuming the excess directly from the nozzle to keep the production environment clean.

It therefore helps to reduce the amount of dry lubricant in the blend, or even eliminate it in the case of new formulations.

The minimal quantity of lubricant sprayed externally onto the tablets can be accurately measured and validated as below the threshold for listing as an ingredient in the formulation.

Technical Info

| Technical data | iSpray |

|---|---|

| Total Height (A) | 1938 mm |

| Floor dimension (BxC) | 600 mm x 1000 mm |

| Packaging | Box on 1 US pallet |

| Netto weight | 300 Kg |

| Brutto weight | 325 Kg |

| Tablet size | 1-28 mm |

| Spraying range | 1,5-15 g/min |

| Requested compressed air | min. 6 bar, 600 Ln/min |

| Compressed air connection | KS4 |

| Noise level | <76 dB |

| Power supply | 110V / 230V |

| Frequency | 50 Hz / 60 Hz |

| Contact parts finishing | RA < 0,5 μm |

| Frame parts | Stainless steel 304 |

| Frame finishing | Brushed 320 |

| Frame mounted on wheels | Yes |

| IQ-OQ protocol | Available |

| Material ceftificates | Available |

| Back-up line available | Yes |

| Cfr 21 Part 11 available | Yes |

| Underpressure control | Yes |

| Flow sensor | Yes |

| Hepa Filter | Standard |

| Available options : | |

| Vacuum valve | Yes |

| Dispensing system | Yes |

■ Accurate spray rate thanks to high precision feeder

■ Consistent amount of lubricant sprayed thanks to the flow sensor

■ Quantity of lubricant sprayed on tablets below 0,1%

■ Back up line to support continuous manufacturing process

■ High under pressure vacuum integrated to prevent lubricant recirculation

■ Retrofittable to all existing tablet presses

■ Available for single and double sided tablet press

■ Fast & easy dismantling and cleaning

■ Complete Audit trail CFR 21 part 11 compliant