TabletSecure360° – Automatic Visual Inspection and Sorting of Tablets, Capsules and Softgels. All-in-one inspection machine for tablets, capsules and softgels with inspection capacity up to 720.000 products/hour.

Tablet/Capsule Inspection

TabletSecure360°

Introduction

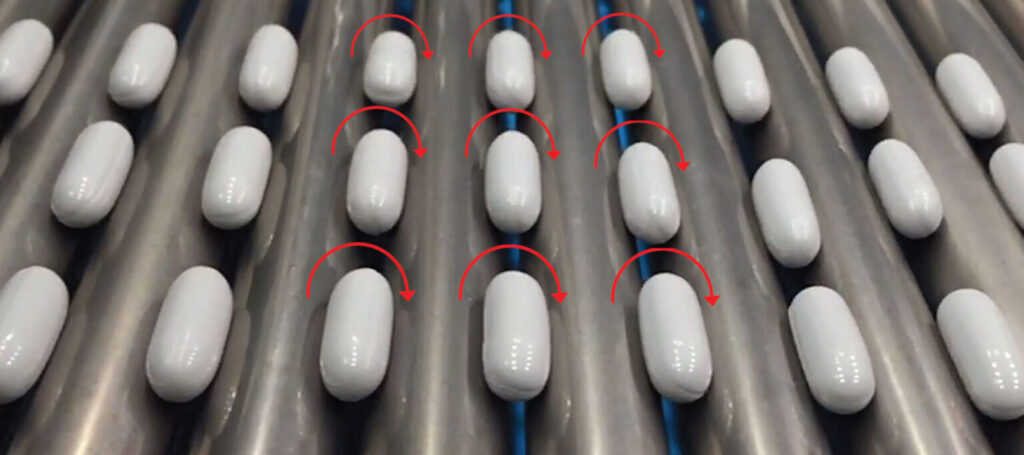

Bulk product is feed in a controlled and reproduceable manner onto our automated roller conveyor system for a secure inspection for each individual tablet or capsule. Multiple images of each product are collected and evaluated while the product is rotating in the camera inspection area. In this way, cross-contamination, quality defects or broken tablets or capsules can be detected.

Suitable for almost all products, including non-rotationally symmetrical ones, such as round tablets, oblongs, two piece capsules and softgel capsules.

Technical Info

- All-in-one inspection machine for tablets, capsules and softgels

- Highest throughput up to 720.000 products per hour.

- Flexible format range from 4 -30 mm

- Inspection of colors, shapes and surface defects

- Inspection transparent products such as softgel capsules

- Individual product rejection with reject verification

- User friendly HMI with touch operation

- Easy cleaning and tool-free changeover

- System guided teach-in process for new products.

- New products can be added by trained operator in less than 10 minutes

- Graphical and chart visualization and settings of tolerances

- User management and audit trail according to CFR 21 Part 11

- Global support available